Quality Control

Product quality often plays a role in determining how an enterprise develops. Therefore, CHALLON has made improving product quality and paying attention to improvement of details the basic orientation of every employee. The company has high-precision CNC lathes, advanced technology and strict, perfect quality management system, all of which are guarantee for stability and reliability of products. In addition, strict screening and tests are performed in all processes of products including casting, machining, assembly, pressure test, packing and finished products.

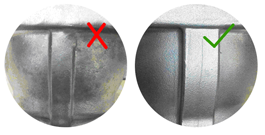

Casting: before machining of valve casting, each casting is strictly screened by the inspection staff to ensure the appearance conformance of each batch of finished products.

Machining: for each casting, every part is machined by the high-precision CNC equipment.

Pressure test: the advanced pressure test equipment used by the company can guarantee products’ conformance to international standard and safety in use.

Hardness test: hardness test should be performed in use of stainless steel valves commonly used in modern life. With test of metal hardness performed on the valve surface by a series of equipment, the company can improve the valves’ safety in use.